|

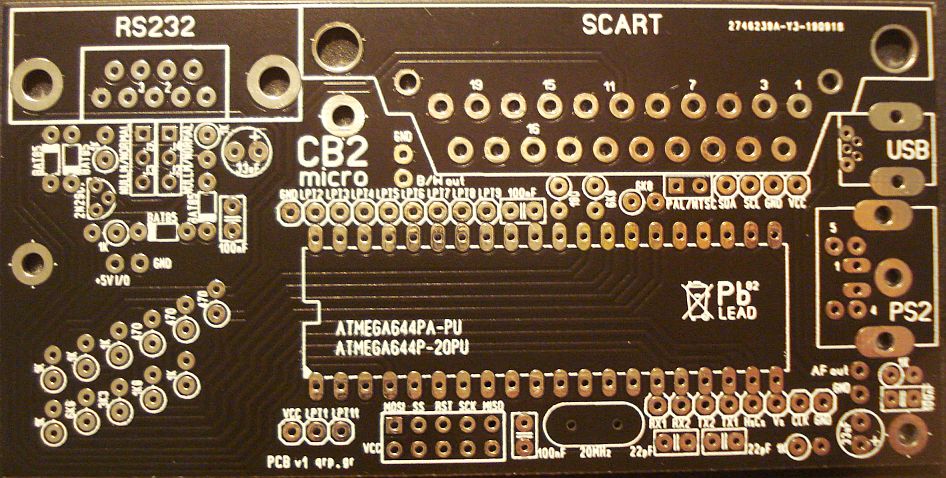

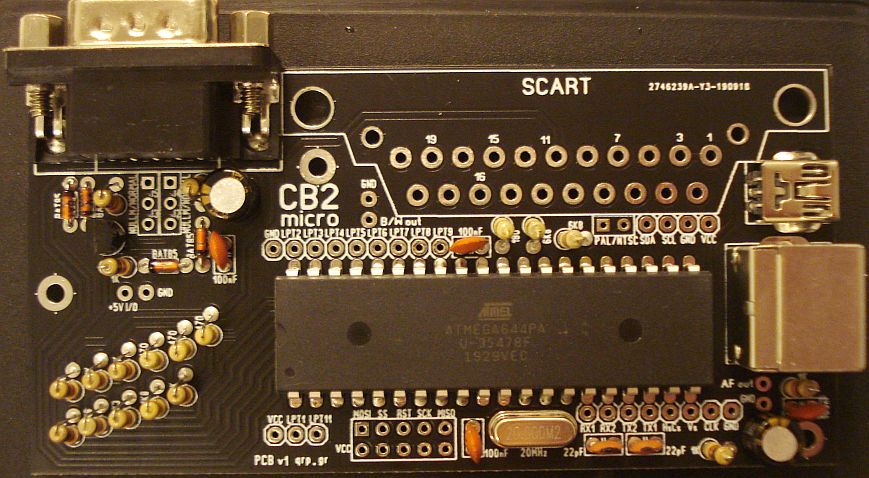

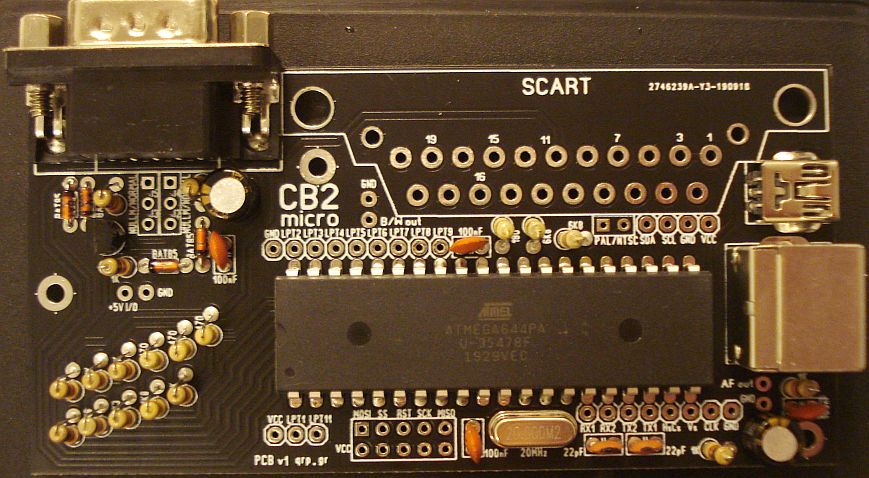

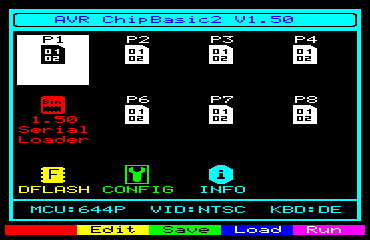

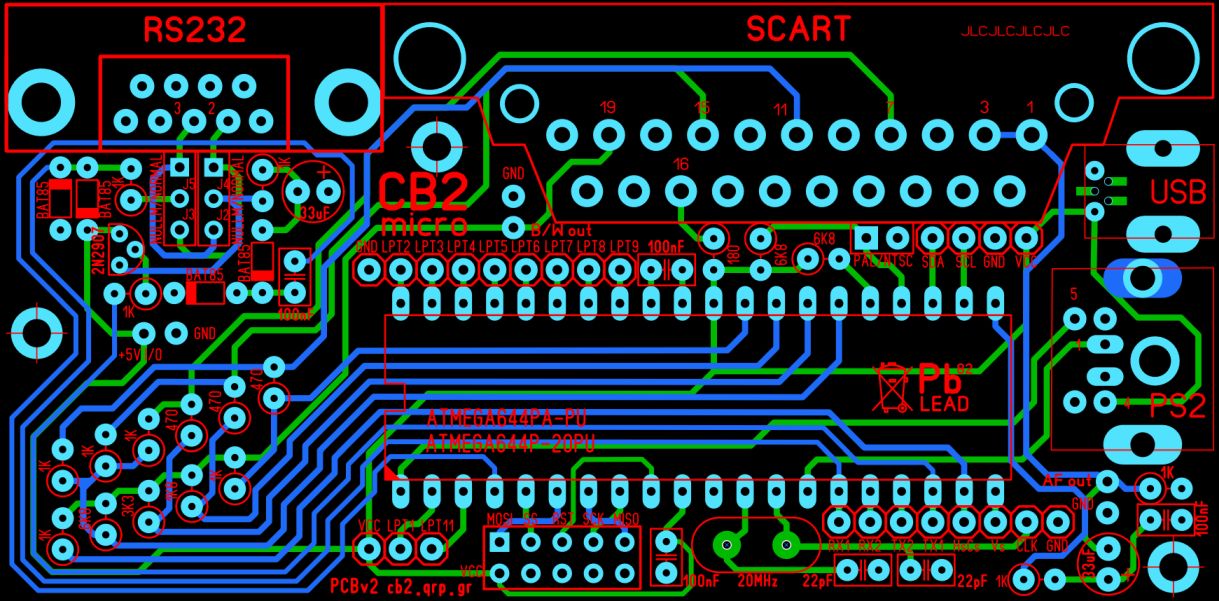

CB2 micro

Building guide

|

| Component

Label (on schematic) |

Component

Value |

Info/Markings/Codes

onto component |

Component

Photo |

Soldered

component photo |

Soldered? |

| - |

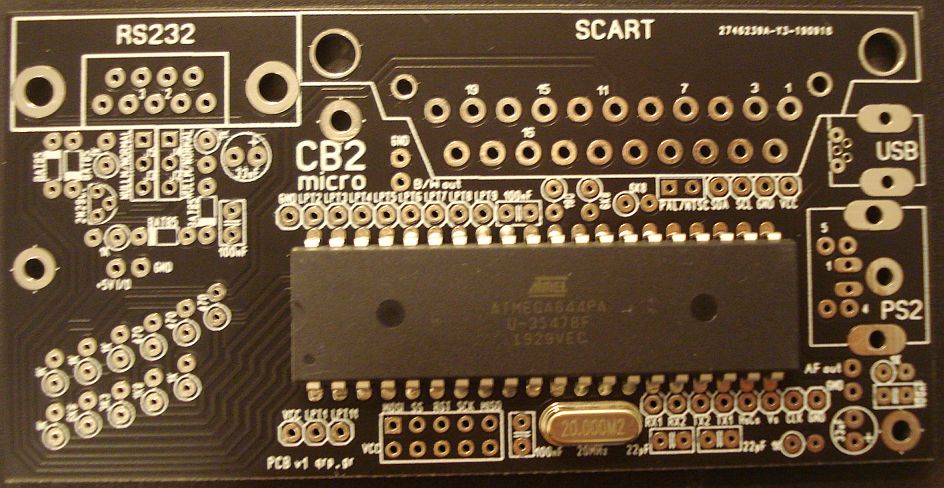

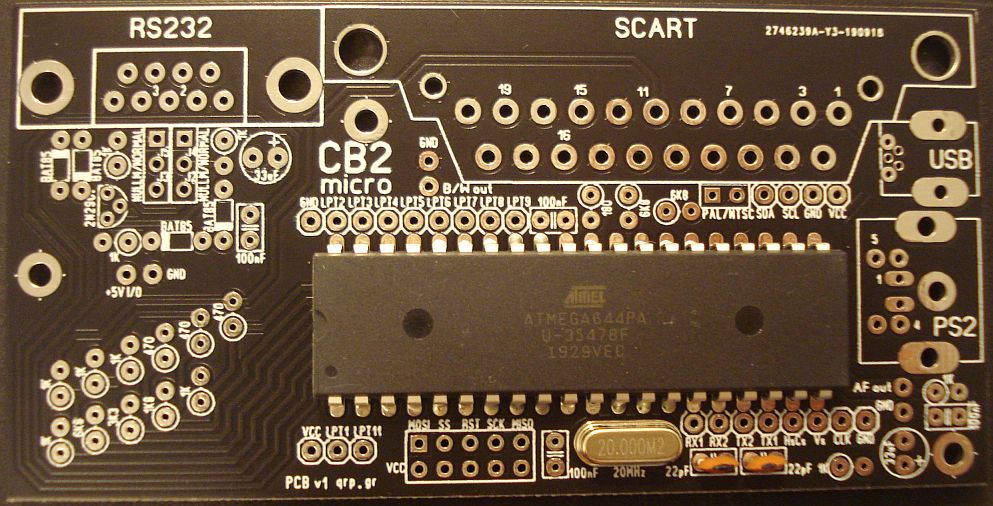

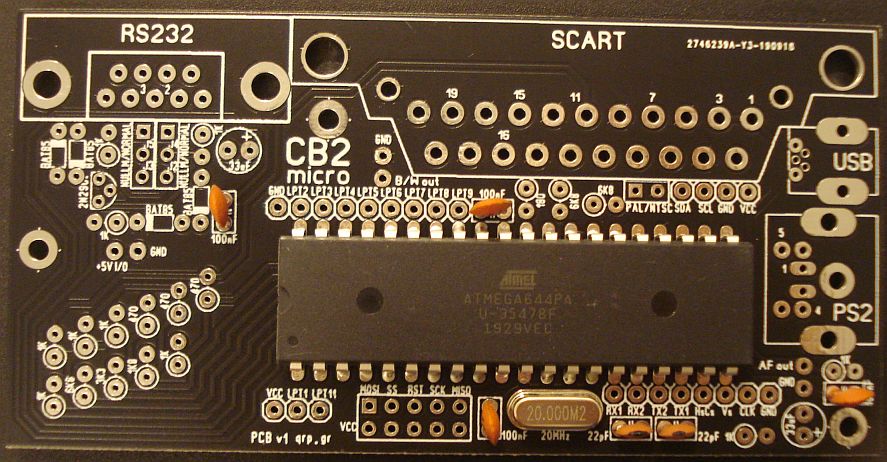

CB2 micro PCB |

CB2 micro * Note, since 2023, some purple PCBs are also available. |

|

- |

- |

| X1 |

20MHz |

20.000 |

|

|

|

| IC1 | ATMEGA644P | ATMEGA644P-20PU or ATMEGA644PA-PU |  |

|

|

| C3 | 22pF |

22 |

|

|

|

| C4 |

22pF |

22 |

|

|

|

| C2 |

100nF | 104 |

|

|

|

| C5 |

100nF | 104 |

|

|

|

| C6 |

100nF | 104 |

|

|

|

| C7 |

100nF | 104 |

|

|

|

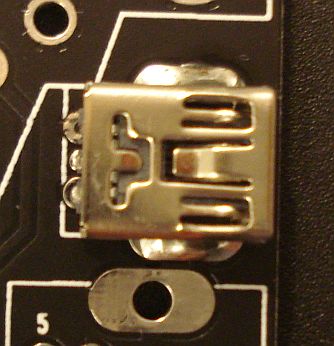

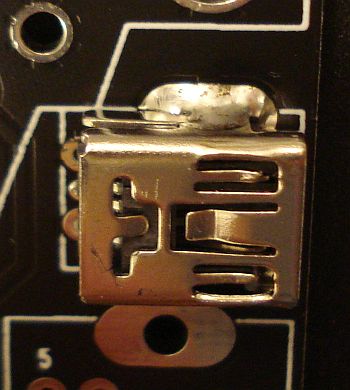

| Mini USB |

Mini USB connector |

Small metal connector * Note, since 2022, the connector comes mounted on the PCB, but you have to solder its pins. |

|

||

| D1 |

BAT85 |

BAT85 |  |

||

| D2 |

BAT85 | BAT85 |  |

||

| D3 |

BAT85 | BAT85 |  |

||

| D4 |

BAT85 | BAT85 |  |

||

| C1 |

33uF |

33uF * Note, since 2022, the capacitor provided is longer. |

|

|

|

| C8 |

33uF |

33uF * Note, since 2022, the capacitor provided is longer. |

|

|

|

| T2 |

2N2907 |

2N2907 |

|

|

|

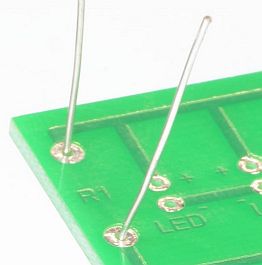

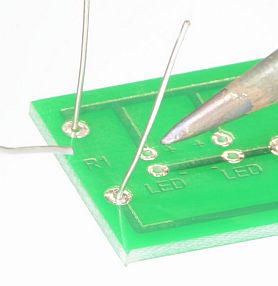

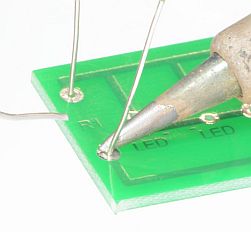

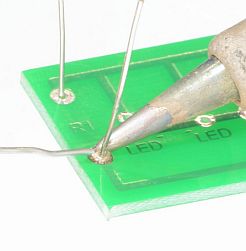

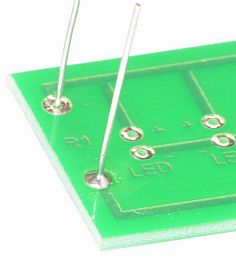

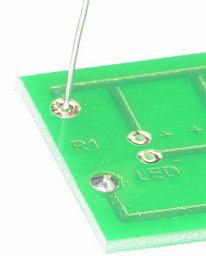

| R1 |

1k |

brown, black, red, gold * Note, since 2022, a blue resistor is supplied. |

|

|

|

| R2 |

1k |

brown, black, red, gold * Note, since 2022, a blue resistor is supplied. |

|

|

|

| R3 |

1k |

brown, black, red, gold * Note, since 2022, a blue resistor is supplied. |

|

|

|

| R6 |

1k |

brown, black, red, gold * Note, since 2022, a blue resistor is supplied. |

|

|

|

| R7 |

1k |

brown, black, red, gold * Note, since 2022, a blue resistor is supplied. |

|

|

|

| R11 |

1k |

brown, black, red, gold * Note, since 2022, a blue resistor is supplied. |

|

|

|

| R12 |

1k |

brown, black, red, gold * Note, since 2022, a blue resistor is supplied. |

|

|

|

| R13 |

1k |

brown, black, red, gold * Note, since 2022, a blue resistor is supplied. |

|

|

|

| R14 |

1k |

brown, black, red, gold * Note, since 2022, a blue resistor is supplied. |

|

|

|

| R18 |

1k |

brown, black, red, gold * Note, since 2022, a blue resistor is supplied. |

|

|

|

| R4 |

6.8k |

blue, gray, red, gold |

|

|

|

| R5 |

6.8k |

blue, gray, red, gold |

|

|

|

| R15 |

6.8k |

blue, gray, red, gold |

|

|

|

| R8 |

470 ohm |

yellow, violet, brown, gold |

|

|

|

| R9 |

470 ohm |

yellow, violet, brown, gold |

|

|

|

| R10 |

470 ohm |

yellow, violet, brown, gold |

|

|

|

| R16 |

3.3k |

orange, orange, red, gold |

|

||

| R17 |

1.8k |

brown, gray, red, gold |

|

|

|

| R19 |

180 ohm |

brown, gray, brown, gold |

|

|

|

| Sub-D 9 (f) |

Dsub-9 male connector |

Big black plastic-metal connector |

|||

| PS2 (f) front |

PS/2 female connector |

Big metal connector. * Note, since 2022, a black connector is supplied. |

|

||

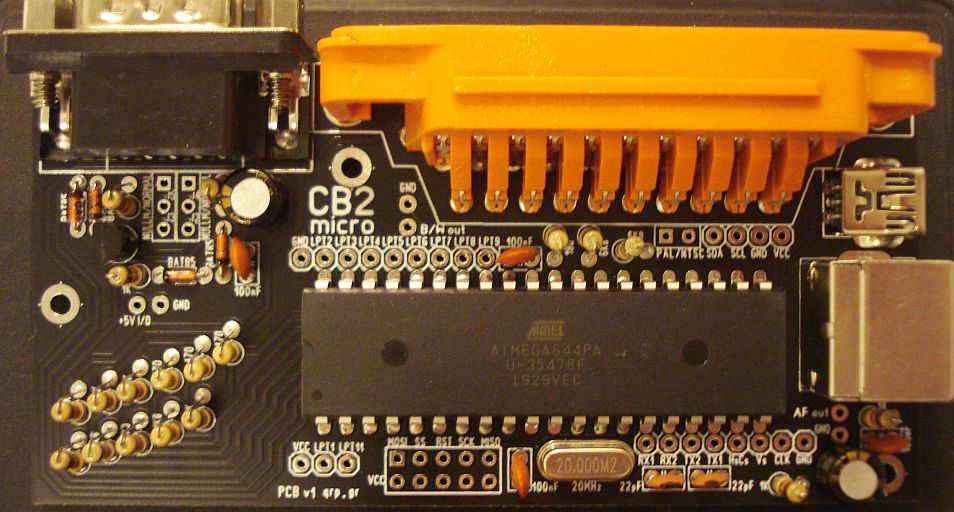

| SCART (f) |

SCART female connector |

Big plastic connector. * Note, since 10 Mar 2023, a black connector is supplied. |

|

|